- Home

- About Us

- Products

- Electronic Plastic Components

- Industrial Plastic Components

- Plastic Bearing Cover

- Plastic End Cover

- Plastic Worm Gears

- Pesticides Plastic Bottle

- Oil Plastic Bottle

- Food Grade Plastic Bottle

- Pharma Plastic Bottle

- Cosmetic Plastic Bottle

- Prototype Moulds

- Horizontal Moulds

- Precision Moulds

- Multicavity Moulds

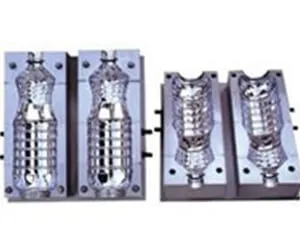

- Plastic Bottle Moulds

- PTFE Machined Parts

- VMC Milling

- CNC Machining Job Work

- Enquiry

- Contact Us